At [Dr. O], we not only sell parts but also integrated protection systems. Let's learn about the five key guardians protecting your equipment's health.

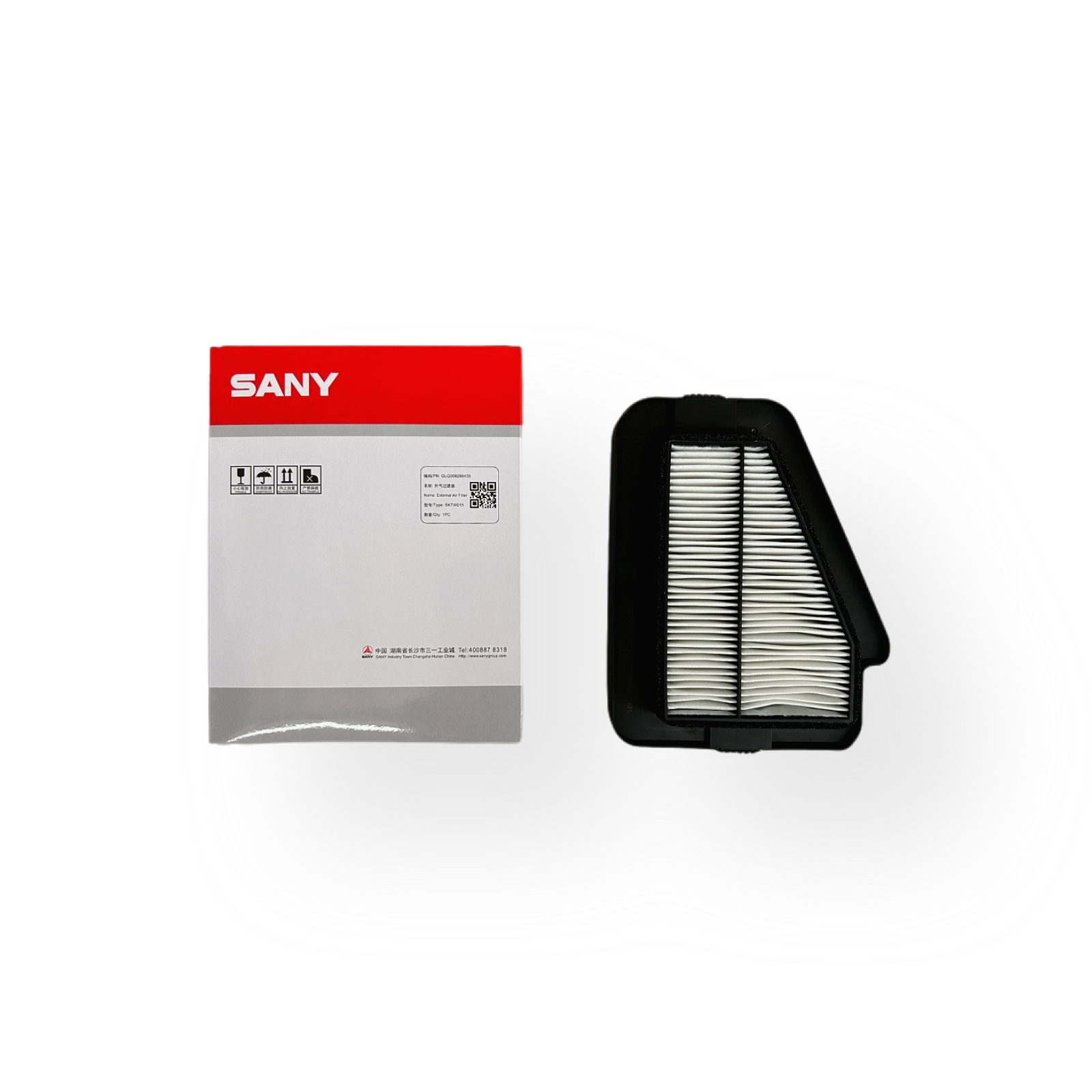

1. Air Filter: The Engine's "Lungs," ensuring your engine only draws in clean air.

Engines need to draw in a large amount of air. Without a high-quality air filter, abrasive dust and particulate matter are directly sucked into the combustion chamber. This can cause rapid wear on piston rings, cylinders, and other internal engine parts, resulting in power loss, increased fuel consumption, and even potentially requiring a complete engine rebuild.

Our advanced air filters use multi-stage filter media (synthetic materials and cellulose) to capture the finest abrasive particles, ensuring your engine breathes smoothly and lasts longer.

2. Oil Filter: The Engine's "Blood Purifier," continuously cleaning the engine's "blood"—the oil.

Engine oil carries away carbon deposits, metal wear particles, and sludge during its circulation. The oil filter's role is to remove these contaminants, keeping the oil clean and efficient.

If dirty and abrasive oil circulates within the engine, it accelerates wear on bearings, camshafts, and other precision components. This can quickly lead to complete engine failure.

Our oil filters use high-quality filter media and check valves to maximize contaminant removal, ensuring clean oil flow immediately upon startup.

3. Fuel Filter/Water Separator: The guardian of the fuel system, protecting fuel injectors and the fuel pump from contaminants and water.

Modern high-pressure fuel systems require extremely high precision. Even tiny particles or small amounts of water can cause serious damage.

Injector blockage, incomplete combustion, and power loss. Water in the fuel can cause corrosion and potentially damage the fuel injection pump instantly—one of the most expensive parts to replace.

Our fuel filters/oil-water separators utilize advanced coalescing media to efficiently remove moisture and capture tiny particles, ensuring clean and dry fuel for optimal performance and extended injector life.

4. Hydraulic Filters: Guardians of Hydraulic Systems, protecting the precision components of hydraulic systems.

Hydraulic systems operate under extremely high pressures. Even contaminants as small as 5-10 microns (fineer than a human hair) can cause wear and tear on pumps, valves, and actuators.

Lack of hydraulic power, unstable operation, and gradual damage to expensive components ultimately lead to high repair costs and unplanned downtime.

Our hydraulic filters are designed to maintain the critical cleanliness required by hydraulic systems, protecting your investment and ensuring smooth, powerful operation.